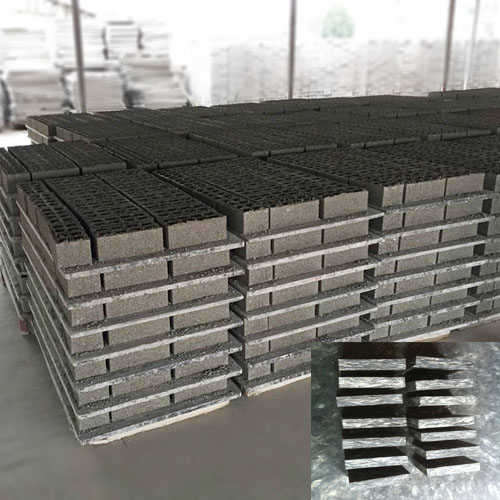

The production of GMT brick pallets is produced by the customers’ constant feedback and opinions. It can be said to be a high-quality pallet that meets the contemporary trend. Because the brick machine pallet is easy to cause uneven water content due to different conditions on both sides of the board, the brick machine pallet

Reasons For Pallet Deformation?