Non-burning brick introduction

Introduction:

The non-burning bricks do not need to be sintered, and can be naturally maintained and steamed at room temperature. The finished bricks produced by the equipment meet the brick standards of the building materials industry, and are ideal equipment for comprehensive treatment and utilization of waste slag, eliminating environmental pollution, saving land resources.

machine:

The main supporting equipment of the non-burning brick production line is the brick-free machine.It is mainly divided into rotary machine, vacuum extruder and automatic hydraulic forming machine. Because the automatic hydraulic forming machine has the characteristics of high automation, large pressing force, good product quality and high output, it has become the first choice for the production line of non-burning brick.

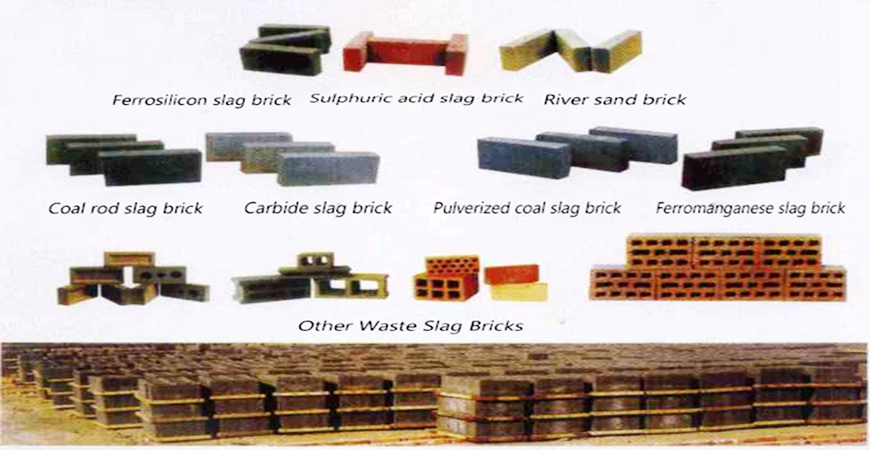

Material:

The brick-free machine has a wide range of material-applicability and can prepare burn-free bricks by using a variety of materials; It is mainly used to suppress the production of burnt-free bricks, steamed sand bricks, refractory bricks and hollow bricks, which are the main raw materials of fly ash, river sand, sea sand, mountain sand.ect

Production Process:

Feeding machine→mixer→belt conveyor→calculator→brick→conservation→finished product→factory

According to the technical requirements of the production line, the following conditions are required:

1. The road is smooth, so that raw materials can enter the factory and the finished products leave the factory.

2. The power supply voltage is 380V and the capacity is 30KVA.

3. The production site should be level and the natural conservation needs to have enough space.

4. Water source, generally tap water.

5. The equipment should be installed in the factory building.

6. The site selection should be as close as possible to the road and farther away from the residential area.

Non-burning brick Prospects:

- The development, promotion and utilization of non-burnt bricks will have good development prospects in China.

- According to relevant national data, in terms of raw materials, China’s solid waste reserves and annual emissions are very large. These wastes not only encroach on a large amount of land, and pollute the surrounding areas. has become a heavy burden for enterprises.

- At present, there are thousands of large and medium-sized coal production enterprises and thermal power generation enterprises in China. Every year, hundreds of millions of tons of industrial waste, such as fly ash, slag, slag, tailings sand, vermiculite, etc., need to be discharged. Try to digest or convert industrial waste.

- It can be seen from this that the use of industrial waste to produce burn-free bricks has become a worthwhile undertaking for saving land, soil, waste, environmental protection

2.Develop new wall materials with non-clay as industrial raw materials.

- Develop new wall materials actively promote energy-saving buildings, which are effective in protecting cultivated land resources, improving building functions and living comfort, industrial optimization and upgrading and An effective way to advance the technological progress of the construction industry.

- Wall materials are an indispensable building material in the construction industry. The construction industry is also the pillar industry of the national economy. It plays an irreplaceable role in promoting the process of China’s modernization. Its huge construction market capacity also provides a very broad prospect for the production of wall materials.

Leave a Reply