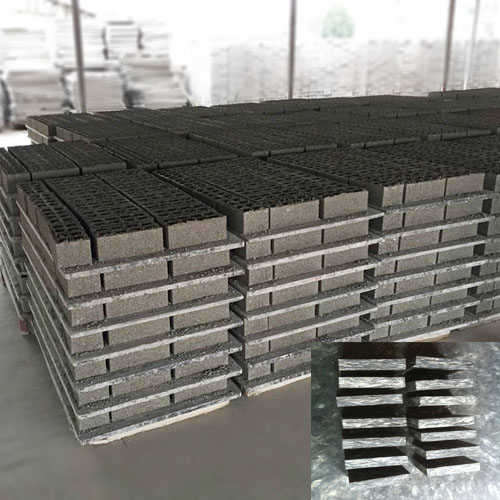

Hollow brick pallets, unburned brick pallets, cement brick pallets are mainly used in hollow bricks, walkway bricks, grass planting bricks, roadside stone bricks and other hollow brick production, supporting the auxiliary products for brick pallets. Its craft is exquisite, requiring waterproof, sunscreen, non-cracking, not easy to deform, wear-resistant, good seismic effect, economic and applicable.

At present, the hollow brick supporting plate materials widely used in the market are: wood supporting plate, bamboo supporting plate, GMT plate, composite supporting plate and so on.

Unfired brick bracket is an auxiliary product in the production of unburned brick.

Follow-up is divided into:

- The pallets made of container boards.

- Pallets (bamboo plywood and wooden pallets) made of nails from used building formwork.

- PVC plastic bracket,

- Black waste synthetic pallets,

- Hsinchu plywood pallet,

- Glass fiberboard.(GMT pallets)

Non-fired brick pallet container board (Liu’an mu), which is widely used at present, is a kind of brick machine pallet. The pallet thickness is 3 centimeters. The pallet material has the characteristics of moderate weight, reasonable price, high hardness, not easy to rise, wear-resistant and durable, and is widely accepted by users.

The notable features of hollow brick and unburned brick bracket products are as follows:

1. The surface is compact, smooth and easy to peel off the concrete surface.

2. Wear resistance and surface crack resistance, no layer.

3. Strong performance, strong resistance to common acidic compounds.

4. Surface color will not change the color of concrete, nor will alkali in concrete change the color of overlay.

5. The bracket is made of three layers of steel nails to prolong the turnover rate of bracket formwork of brick machine.

6. Strong water and climate resistance

7. Light weight. If the length is 85 cm × 55 cm × 28 cm, the weight is only 9 KG/block, while the weight of PVC plastic sheet is 26 KG/block.

Leave a Reply