Non-burning brick characteristics:

It is not used in any other wall bricks. With reasonable scientific formula, coagulant and trace chemical additives are added in a certain proportion, so that the particle size, humidity and mixing degree are strengthened by reasonable equipment technology to achieve the best plastic state. High-pressure press forming, the brick body is quickly hardened, the longer the time, the better the effect, the practicality of the brick is good, the wall is not immersed, and the appearance is neat. Due to its high strength, durability, dimensional standard, complete shape and uniform color, it has a simple and natural appearance, and can be used as a clear wall or any exterior decoration. Therefore, it is a promising replacement product for replacing clay bricks.

Principle:

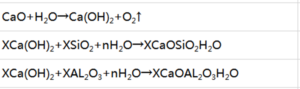

Industrial wastes such as fly ash, coal gangue and slag contain high silica, alumina and iron oxide. After mixing the raw materials, they are fully hydrated to form silicon and aluminum glass. This glass body is hydrated. The combination of calcium oxide produces a chemical reaction called “pozzolanic reaction” whose chemical equation is as follows:

The hydrated silicon (aluminum) silicate in the chemical reaction is a colloidal glass body. The colloidal glass body is unstable, but under the action of the additive, it gradually solidifies with time and forms a high-strength network. Structure, combined with the rational allocation and maintenance of raw materials, thus forming the strength of self-supporting bricks.

Unburned brick application

Highly polluting enterprises:

The waste tailings produced by mining enterprises can be used to produce non-burning bricks. The manufacturers of non-burning brick machines with nearly 30 years of experience in production line installation have many iron tailings, tin tailings, gold tailings and other non-ferrous metal tails. With the experience of mine cooperation, the daily processing capacity of the tailings produced by the single-line production line of burn-free bricks is as high as 300 tons! For mining enterprises with large tailings production, it is possible to adopt measures for simultaneous production of multiple production lines.

Heavy polluting enterprises:

The printing and dyeing sludge produced by the printing and dyeing enterprises can be used to produce non-burning bricks. The production of printing and dyeing sludge is not large but the pollution is high. It has always been the focus of the environmental protection department and the media. Our printing and dyeing sludge brick making technology can produce a variety of brick types with one brick machine.

Other pollutants:

Such as air high pollutant fly ash; calcium carbide slag generated after calcium carbide hydrolysis; building waste and other pollutants generated after building demolition can be produced into non-burning bricks by economical and environmentally friendly, recyclable bricks.

The non-burning brick machine has small investment, simple process and large profit margin. It can not only effectively treat pollutants for high-polluting enterprises, but also bring additional high returns to the enterprise and achieve a harmonious state of economic and environmental development at the same time!

Good partner for Non-burned bricks GMT brick pallet

Leave a Reply